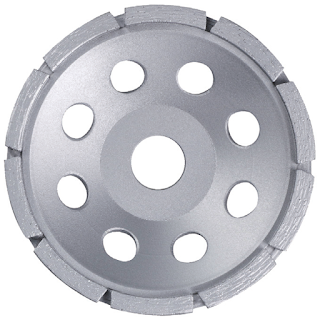

GET TO KNOW YOUR DIAMOND BLADE

Understanding your diamond blades can help you make educated decisions in the field, save time and decrease the chance of injury. In this post, we will break down the components of a diamond blade, and the functions of each part. GET TO KNOW YOUR DIAMOND BLADE Understanding your diamond blades can help you make educated decisions in the field, save time and decrease the chance of injury. In this post, we will break down the components of a diamond blade, and the functions of each part. Parts of Blade SEGMENTS The segment is best described as the ‘ teeth ’ around the blade. There are two parts that make up a segment, the bond, and the diamond. It is important to note that the segments do not cut material like a blade used to cut wood. Instead, they grind away the material with their diamonds, which do all of the grinding work. The amount of diamonds, quality of diamonds, and the size of the diamonds in a segment all factor into cutting speed and the life of the blade. The bond holds