What You Should Know About Diamond Saw Blades

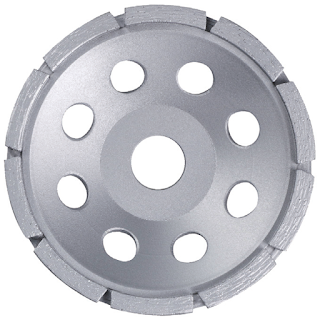

As a Gasoline Diamond Blade Manufacturer, share with you. Diamond saw blade is a cutting tool, which is widely used in the processing of hard and brittle materials such as concrete, refractory materials, stone, ceramics and so on. The diamond saw blade is mainly composed of two parts; the base body and the cutter head. The base is the main supporting part of the bonded cutter head.

The cutter head is the part that cuts during use. The cutter head will continue to be consumed during use, but the matrix will not. The reason why the cutter head can cut is because it contains diamonds, which is the most important part. Hard material, it friction cuts the processed object in the cutter head. The diamond particles are wrapped in metal inside the cutter head.

Sintered Diamond Saw Blades

Process classification

1. Sintered diamond saw blade: divided into cold pressing sintering and hot pressing sintering, pressed and sintered.

2. Welding diamond saw blades: divided into two types: brazing and laser welding. Brazing is to weld the cutter head and the base through a high-temperature melting medium, such as high-frequency induction brazing saw blades, vacuum brazing saw blades, etc.; laser welding The contact edge of the cutter head and the substrate is melted by a high-temperature laser beam to form a metallurgical bond.

3. Electroplating (brazed) diamond saw blade: the blade powder is attached to the substrate by electroplating. Since 2012, the country has gradually eliminated the production of electroplated diamond products, mainly because of serious pollution.

Different types of diamond saw blades are selected for different materials, and different powder formulations are suitable for the characteristics of different materials, which have a direct impact on the quality, effect, pass rate, and cost and benefit of the material product.

The factors that affect the efficiency and life of diamond circular saw blades include sawing process parameters, diamond particle size, concentration, and bond hardness. According to the cutting parameters, there are saw blade linear speed, sawing concentration and feed speed.

Saw blade speed:

In actual work, the linear speed of diamond circular saw blades is limited by the equipment conditions, the quality of the saw blade and the nature of the sawn stone. In terms of the best service life and cutting efficiency of the saw blade, the linear speed of the saw blade should be selected according to the properties of different stones. When sawing granite, the linear speed of the saw blade can be selected within the range of 25m~35m/s. For granite with high quartz content and difficult to saw, the lower limit of the saw blade linear speed is appropriate. In the production of granite tiles, the Sintered Diamond Saw Blades used are smaller in diameter, and the linear speed can reach 35m/s.

评论

发表评论